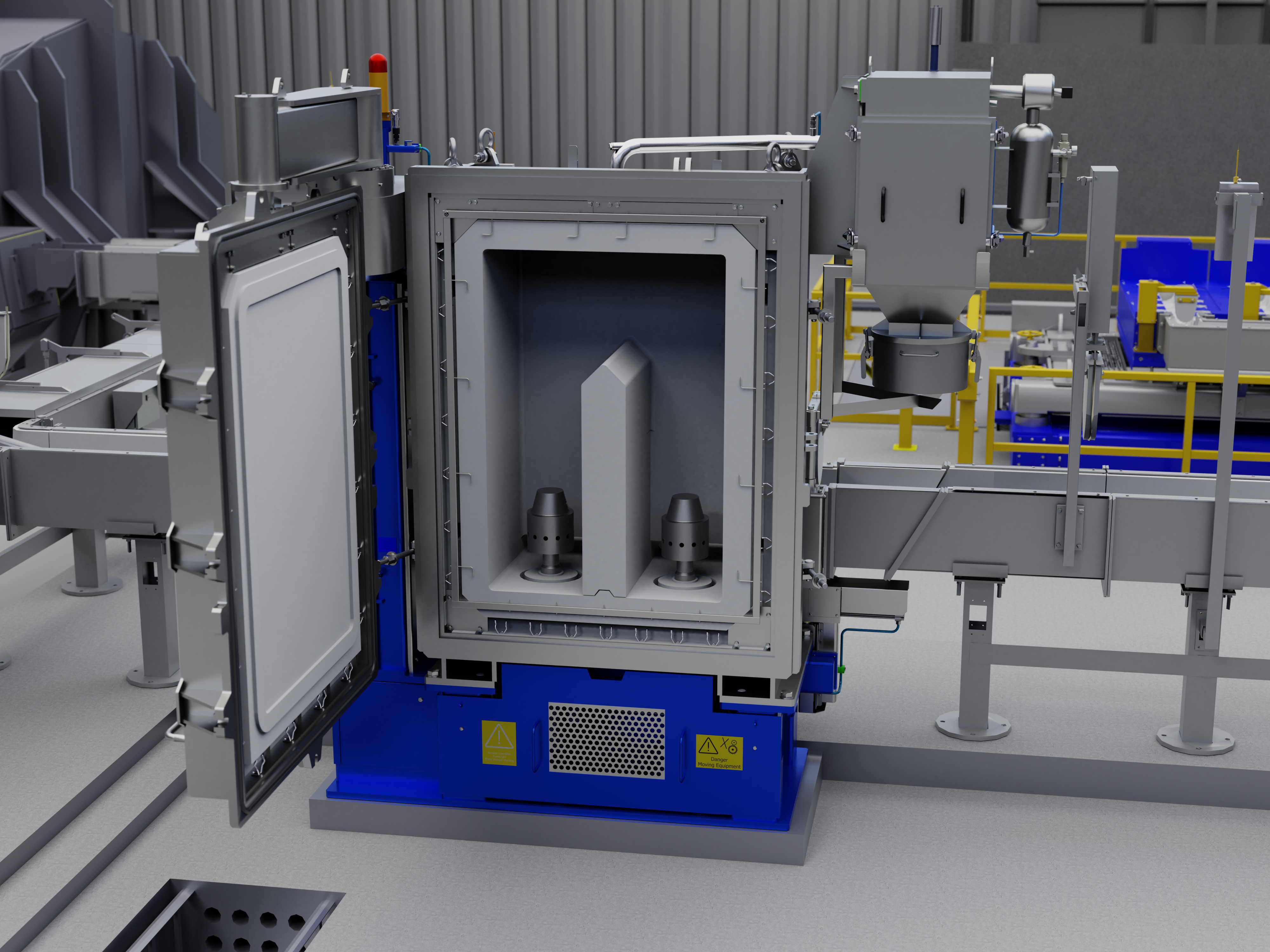

Inline melt refining

State of the art degassing

The drain-free Hycast I-60/I-25 Siphon Inert Reactor (SIR) in-line filter system is the benchmark for refining, degassing and particle removal of molten aluminium in-line between the furnace and casting machine. This technology has been in operation since its introduction in 2001 and is throughly tested and verified in operation.

Technical features:

- Unique melt refining concept with elevated metal above launder through underpressure

- Bottom-mounted rotor system

- Excellent removal of Hydrogen and inclusions

- No mechanical filtration system required downstream for extrusion ingot lines

- Exceptionally low dross generation due to reactor inert atmosphere

- Low operational cost due to few rotors - gas usage only when in operation

- Easy maintenance and no complex hydraulics

Design features:

- Small footprint and easy to adapt to existing casting lines

- Few components and short installation time

- Sloped reactor bottom to drain metal into launder after casting

- Electrical preheating system with hot air (no preheating needed between casts during normal operation)

- Precast monolithic refractory lining with short relining times

- Two standard designs for all flow rates, I-25 and I-60

I-25 SIR

- I-25 SIR for metal flow rates up to 25mt/hour

- Unique design with one bottom-mounted rotor

- Elevated metal level inside reactor to achieve excellent removal efficiency

- 100% inert reactor

- 100% drain free reactor

- Fully automated

- Suitable for all alloy series

I-60 SIR

- For metal flow rates up to 75mt/hour

- Unique design with two bottom-mounted rotors

- Elevated metal level inside reactor to achieve excellent removal efficiency

- 100% intert reactor

- 100% drain free reactor

- Fully automated

- Suitable for all alloy series